Direct mounting technology

Direct mounting is a method of fastening to solid building materials using high-strength nails and studs. The fasteners are mounted using a mounting gun or a special screwdriver. Mounting pistols, in turn, can work due to the energy of powder cartridges, gas cylinders or a battery.

Traditional mounting methods VS direct mounting

|

Eliminates the need for preparation and refinement of the base material

Unlike welding or end-to-end bolting, Hilti mounting solutions eliminate the need for preparing the base material and finalizing it after fixing. This significantly reduces the total installation time, while providing reliable protection against corrosion.

|

|

No need for a qualified welder

The direct mounting technology is easy to use and can be used by installers without special training, unlike welding, which involves the involvement of a certified welder.

|

|

|

|

Access is required only to one side of the structure

Unlike through-bolt fastening or fastening with clips, the Hilti direct mounting technology does not require access to the back side of the structure.

|

|

Suitable for all weather conditions and does not require an external power supply

Hilti's pointed solutions are designed for powder mounting tools, so they can be used in all weather conditions. Cordless drills used for blunt-ended fasteners are designed for harsh operating conditions, so they can be used in almost any weather. In addition, the wireless instruments are powered by lithium-ion batteries with a voltage of 22 V, so network power sources are not required.

|

|

|

|

Certified solution for the most complex tasks

Hilti fasteners are designed to work in various operating conditions. The claimed scope of application of fasteners is confirmed by permits received fr om the Ministry of Construction of the Russian Federation, the Russian Maritime Register of Shipping and other international certification bodies.

|

|

Installation quality that is easy to check

The correctness of the installation of Hilti fasteners is checked by the height of the mounted element. The control can be carried out using improvised means or a verification template.

|

|

|

|

A truly corrosion-resistant mount

Due to the presence of a sealing washer made of EPDM rubber, Hilti fasteners with a blunt tip can be operated in environments with varying degrees of aggressiveness.

|

|

|

Powder mounting pistols have the designation DX (fr om it. Direktmontage - direct installation). They are intended, first of all, for general construction works and the device of fasteners to metal structures. The use of powder cartridges as an energy source makes the gun independent of weather conditions.

|

Safety:

5 degrees of protection are implemented in the powder technology:

- The piston principle-the piston absorbs up to 90% of the energy of the shot, which eliminates the danger of shooting through the base material.

- Safe trigger mechanism - the trigger engages with the feed mechanism only if the "support heel" around the muzzle is pressed with the entire surface to the base material.

- Contact pressure sensor-the tool will not fire until it is pressed against the base material with a force of 50 N or more.

- Safety in case of falling-pistols are equipped with a protection mechanism against a shot when the pistol falls and hits a hard surface.

- Protection against an involuntary shot - the shot is made only if the algorithm of operation is observed (press + shoot).

|

Characteristic features:

- The energy source of the shot is powder gases. Therefore, not only nails are needed for the shot, but also cartridges.

- Due to the high volume of the shot, they are usually used outdoors.

- They have a small combustion chamber.

- They have a high shot power.

- Regular cleaning is required.

|

|

Gas mounting guns have the designation GX (gas). They are used for interior decoration, as well as for fixing engineering networks. Such pistols have less power, so they are usually not used in general construction works.

|

Safety:

Implemented 4 degrees of protection:

- Safe trigger mechanism - the trigger engages with the feed mechanism only if the "support heel" around the muzzle is pressed with the entire surface to the base material.

- Contact pressure sensor-the tool will not fire until it is pressed against the base material with a force of at least 50 N

- Safety when falling - the gun will not fire when falling

- Protection against an involuntary shot - the shot is fired only if the algorithm of operation is observed (press + shoot)

|

Characteristic features:

- The energy source of the shot is gas, so nails and a gas cylinder with a special gas mixture will be required for the shot.

- They have a large combustion chamber.

- The power of the shot of a gas pistol is lower than that of a powder gun, which means that the recoil is less. For applications such as, for example, fixing a cable or a profile for drywall, when the installer makes hundreds of fasteners per shift, this is an important factor. In addition, the lower power also allows you to aim at a silicate brick.

- Cleaning is not required (except for a gun on wood).

|

Three fast and reliable ways to attach to steel

|

|

|

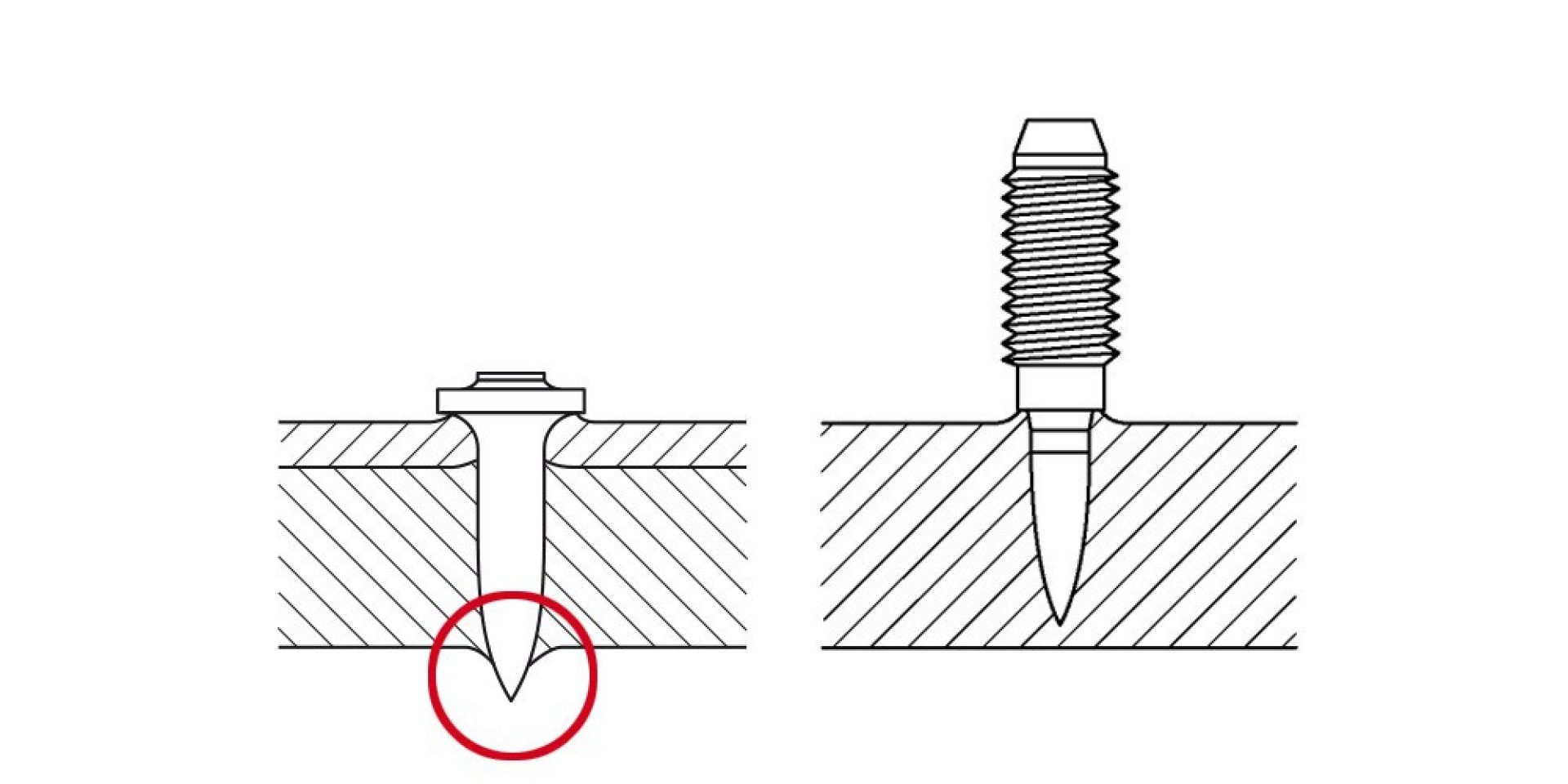

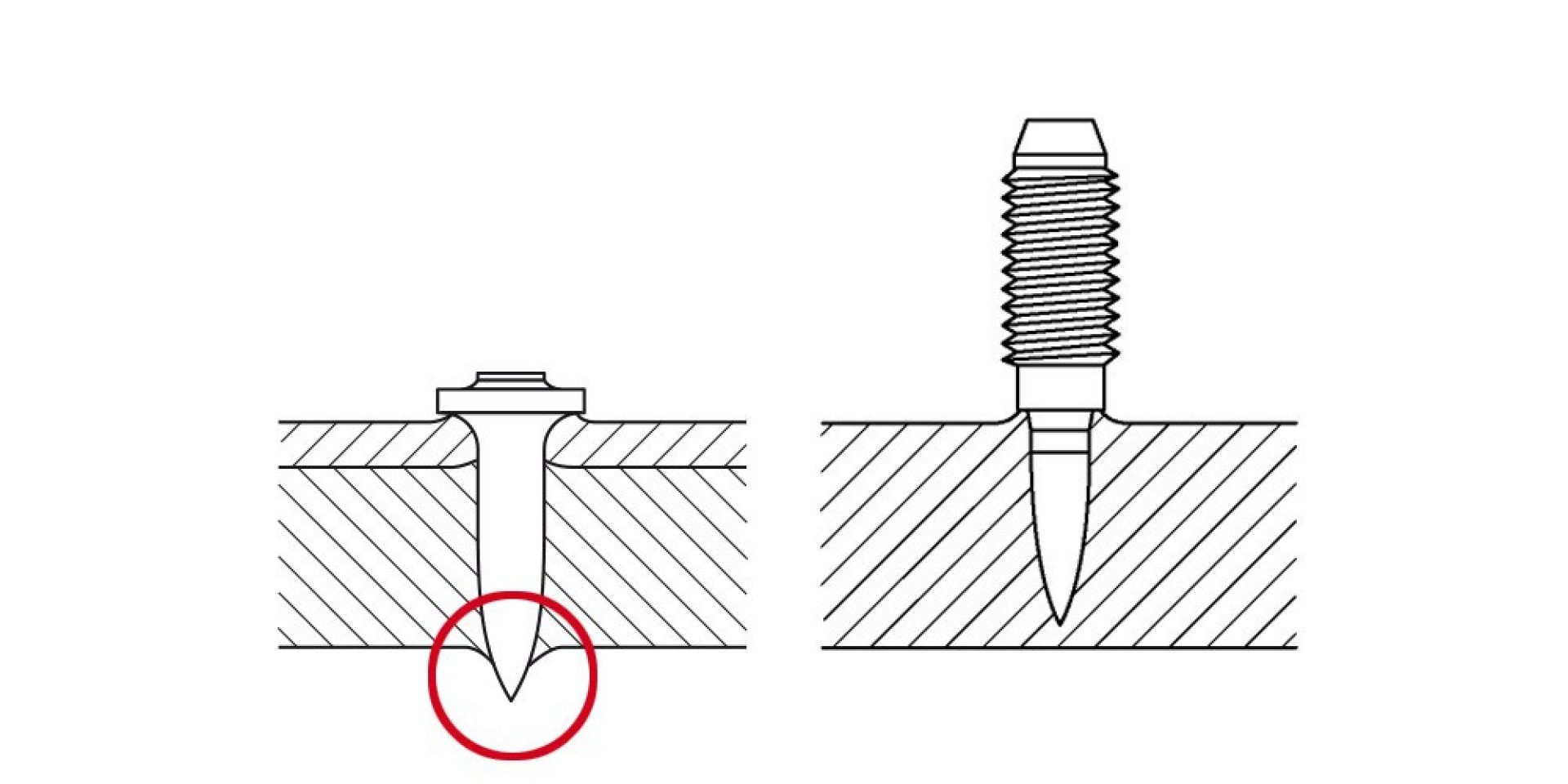

Fixing with a nail (sharp tip)

A fastening technology in which a steel fastener with a sharp tip is targeted.

Suitable for high-frequency mounting, where the mounting process can last only a few seconds.

Stainless steel fasteners for moderately corrosive environments wh ere drilling through the base steel is allowed.

|

|

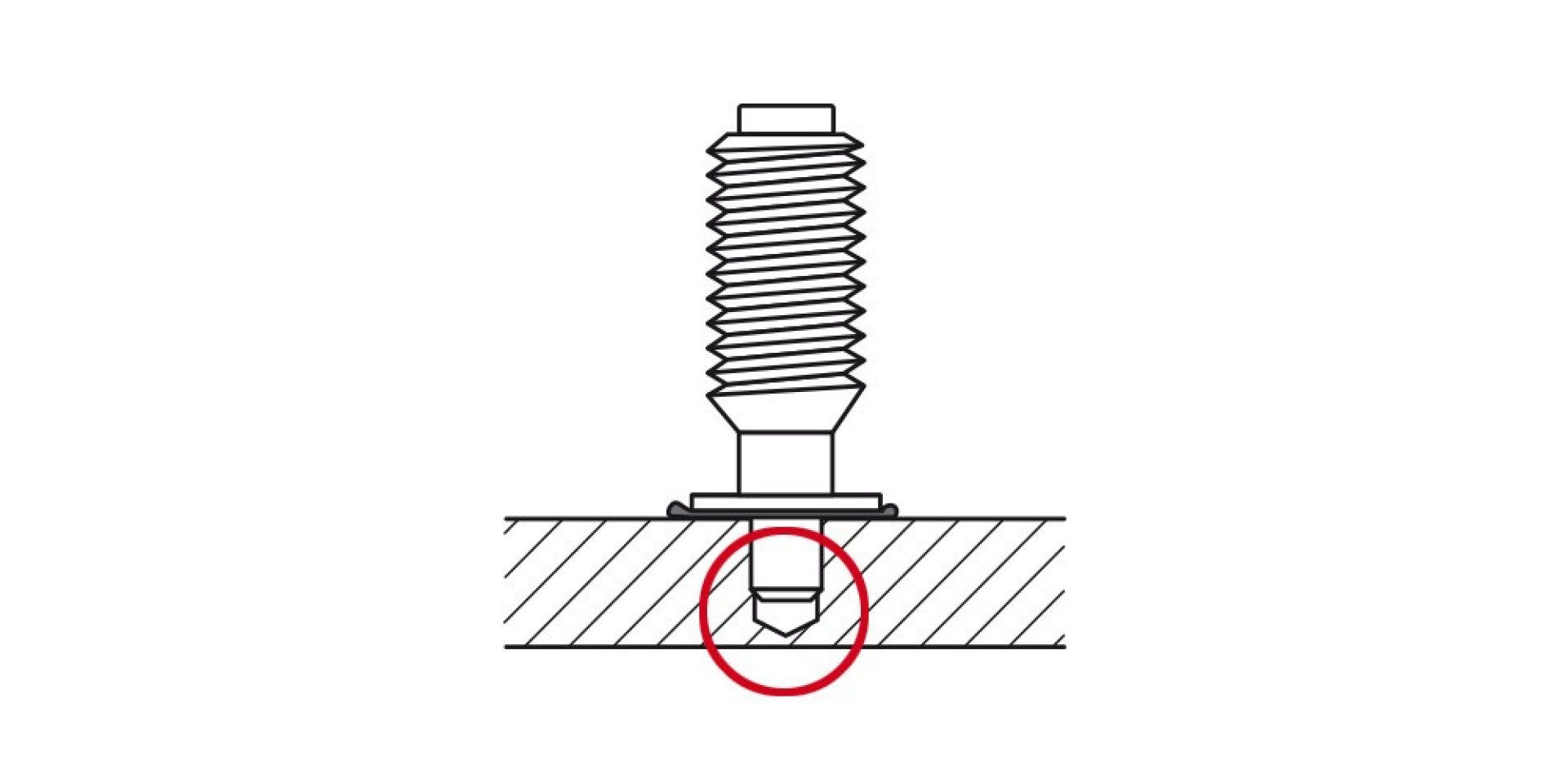

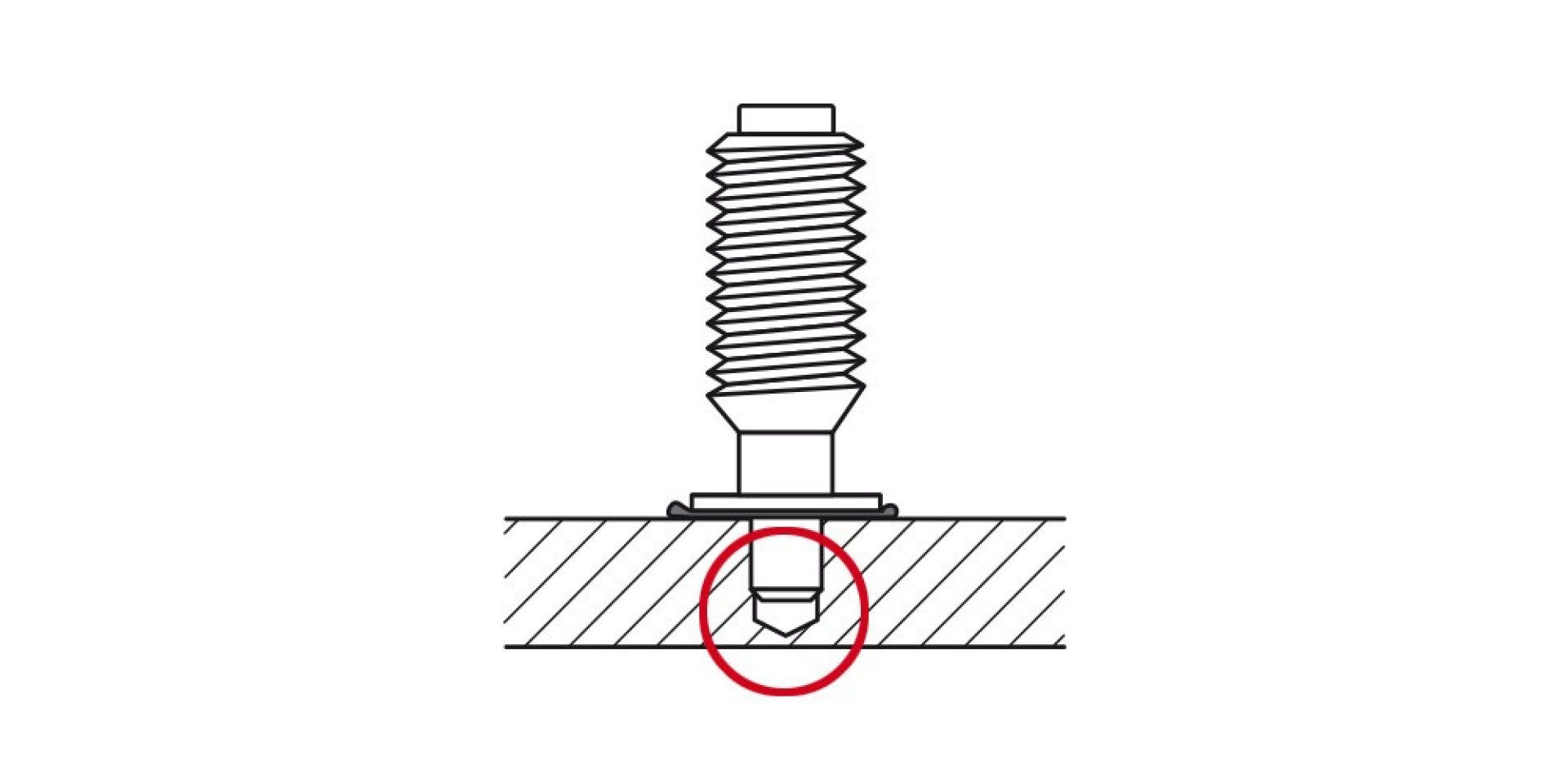

Mounting with an X-BT stud with a blunt tip

A revolutionary fastening technology, wh ere the X-BT stainless steel fastener with a smooth cylindrical or conical leg is aimed with a powder mounting tool into a pre-drilled hole in the base material, creating a high-quality connection.

- No damage to the anti-corrosion coating in cases of non-through drilling

- Fixing is done in less than 2 minutes. Duplex stainless steel fasteners are suitable for highly corrosive environments

Fiber Reinforced Polymer (FRP) / Duplex stainless steel fasteners for moderately corrosive environments.

|

|

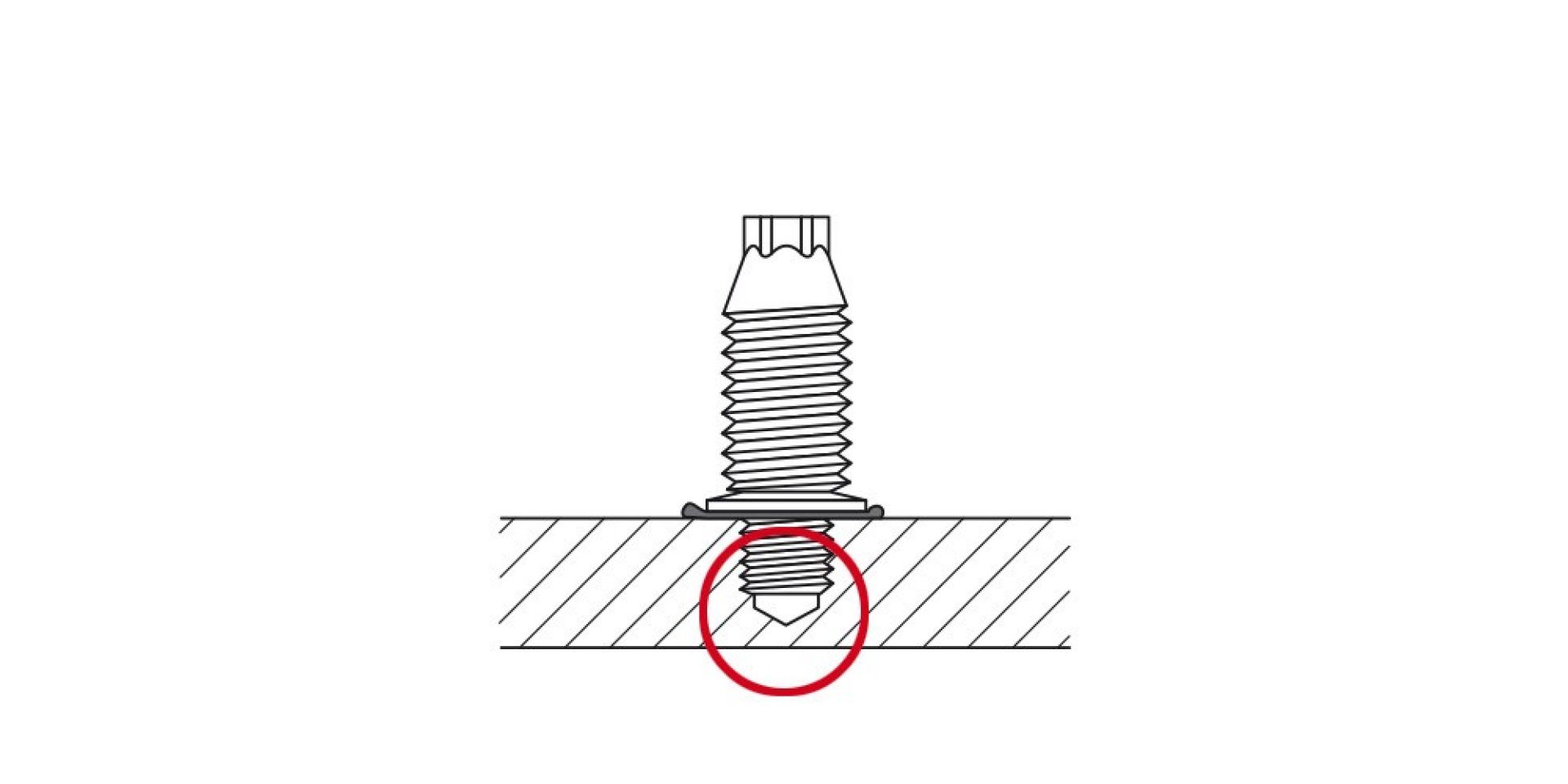

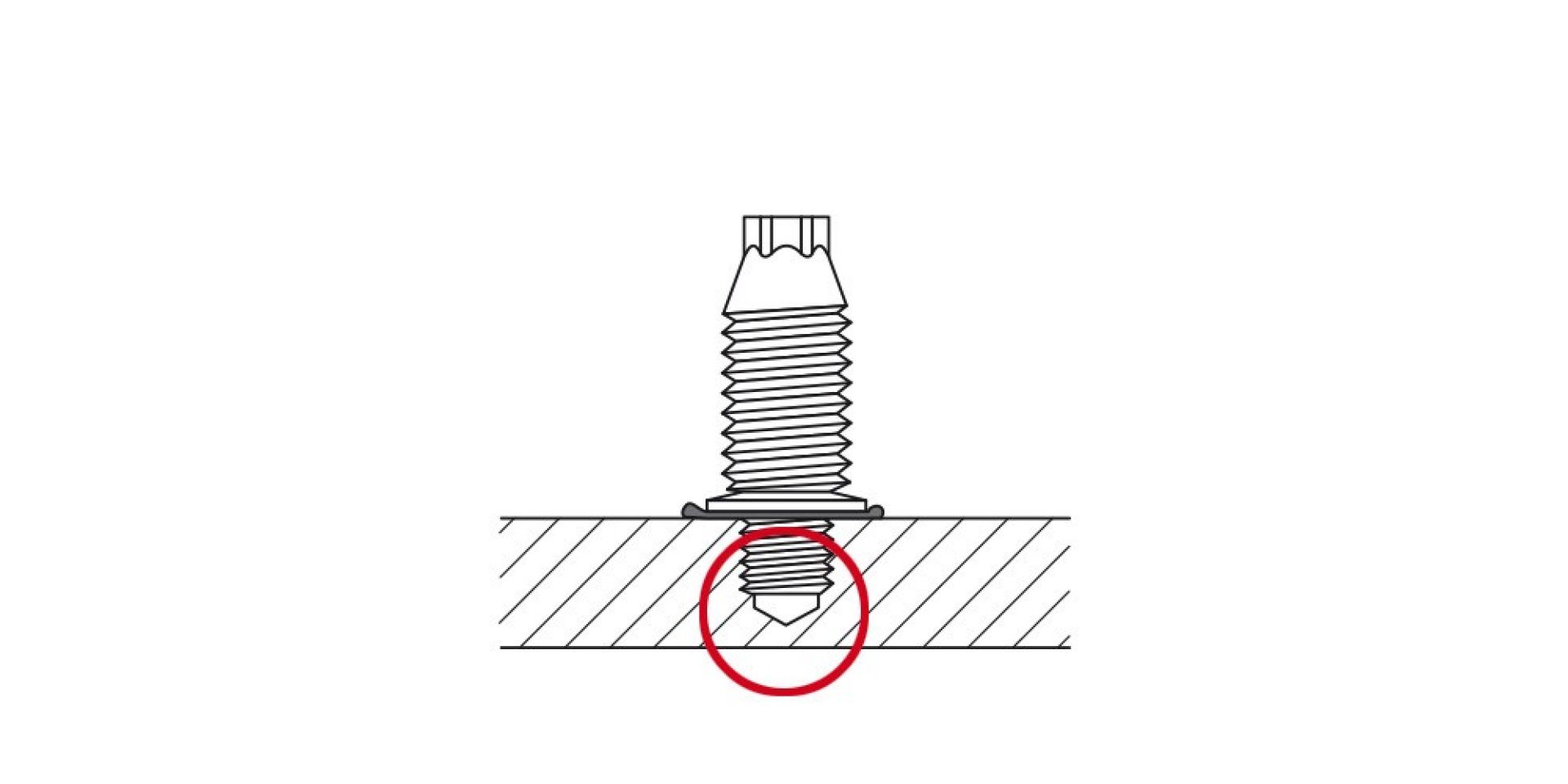

Mounting with a threaded stud-screw S-BT

S-BT is a simple and reliable solution that does not require the use of wired tools or heavy equipment to install. Suitable for use in a mildly aggressive environment (C3) on coated steel. Easy installation in hard-to-reach places. Suitable for use on steel with a thickness of 6 mm or more. Re-processing of coated steel is not required.

- No damage to the anti-corrosion coating in cases of non-through drilling

- Fixing is done in less than 2 minutes. Duplex stainless steel fasteners are suitable for highly corrosive environments

Fiber Reinforced Polymer (FRP) / Duplex stainless steel fasteners for moderately corrosive environments.

|

|

Mounting mechanism in the base material

When attaching to steel, the following processes occur:

When attaching to steel, the following processes occur:

- Foot friction in the base material

- Wedging

- Sintering

If we hammer a nail or stud into the base material with a gun and make a cut, we will notice that, unlike self-tapping screws or other fasteners for steel, dowel nails and other direct mounting elements do not reduce the mass of metals in the cross section. That is, it does not affect the strength characteristics of the section. The nail is held due to the fact that when an element enters the base material, it pushes it apart and then compression is obtained by the base material, which tends to occupy this void.

In addition to this mechanism, there is friction, as with any fastener. Many elements on their legs have notches, which also additionally create this friction.

The peculiarity of a dowel nail with a sharp end is that at the tip of the nail, when it enters the base material with high kinetic energy, the tip is heated and sintered with the base metal.

Bearing capacity of the elements

The recommended load is the calculated resistance of the fastener, taking into account all possible reliability coefficients. The ultimate (destructive) force on the element depends on the characteristics of the base material and, as a rule, is 5-7 times higher than the recommended values.

Operation under special conditions

|

|

Studies have shown that low temperature conditions not only do not reduce, but even slightly increase the bearing capacity for pulling out fasteners.

Most fasteners have a recommended application range from -40 to +100 S, but in the Hilti portfolio there are special elements that have been tested at -170 S.

|

Most of Hilti's portfolio of direct mounting techniques is designed for use in special conditions, including under the influence of vibration load.

The recommended loads can be found in the Manual for Direct Mounting Techniques.

|

Some of the fasteners presented in the company's portfolio have been tested and are approved for use in seismic conditions.

|

When attaching to steel, the following processes occur:

When attaching to steel, the following processes occur: